Project Information

Background:

The client had installed an MBR plant that was suffering blockages and high levels of maintenance and operational costs. The existing screens had a 3mm perforation but were still allowing too much through to the MBR’s, 1.5mm perforated drum screens also supplied by CSO were installed and a system was needed to remove the solids and convey them into a skip.

Application:

Removal and compaction of solids greater than 1.5mm in two directions from the drum screens into a waste disposal skip.

Solution:

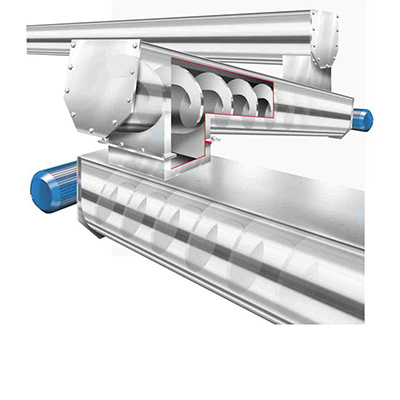

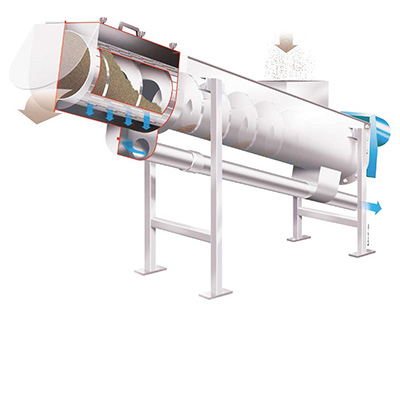

Design and manufacture 1 No Lackeby Shaftless screw press to reduce the bulk of the screenings and convey them to a skip.

Performance:

Successfully reduced the bulk of waste and depositing it into a skip.

Project Data:

Model: SSP 260

Capacity: 3 m3/hr

Dry Solids, Out: 25%

Products featured in this case study

Lackeby Shaftless Screw Conveyors

Lackeby Shaftless Screw Conveyors

Lackeby Shaftless Screw Press

Lackeby Shaftless Screw Press