Pasteurisation

Scope of Equipment

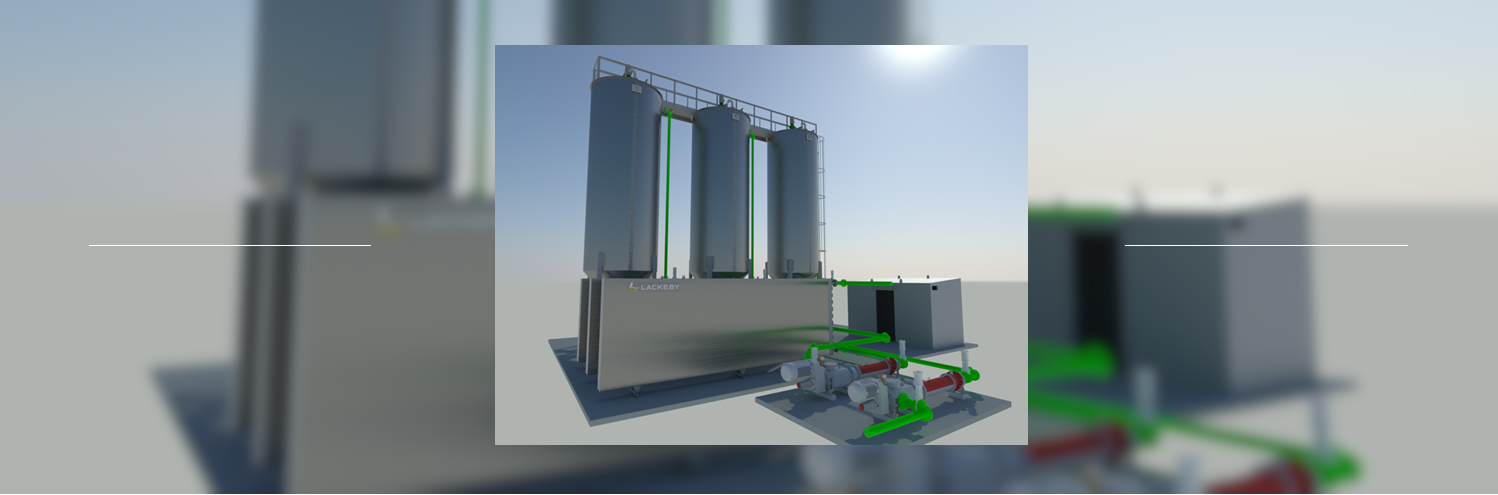

The CSO “3VP” Pasteurisation turn-key system is designed around the Lackeby Heat Exchanger that CSO have supplied for sludge digestate applications for more than 20 years. The unique design of the Lackeby heat exchanger provides not only world leading heat transfer coefficients, it also has hinged end plates that allow the unit to be rodded through simply and quickly in the event of fouling, the end plate design also provides a smaller footprint than conventional tube in tube designs.

The “3VP” system comprises the following equipment:

-

3 No Insulated Pasteurisation vessels

-

3 No “Lackeby” insulated Heat exchangers

-

Pumps

-

Interconnecting pipework & Valves

-

Instrumentation

-

HMI – PLC control

Process Description

The “3VP’’ is a continuous process that employs three pasteurisation vessels utilising a rotating cascade principal. The digested sludge passes through the heat exchanger (HEX1) where it is preheated using the waste heat recovered from the pasteurised sludge, to recover heat and then into the second unit to raise the temperature to just over 70°C and then into one of the vessels where it is held at 70°C for one hour before being discharged via the third heat exchanger where the excess heat is recovered. The first (HEX1) and third (HEX3) are connected by water loop allowing the recovered heat to preheat the incoming sludge. This design maximises energy efficiency. The three vessel system allows one tank to be holding, whilst the other two are either filling or emptying to ensure continuous operation. The overall system is controlled via HMI-PLC control panel which ensures full traceability and the possibility for batched production.

Benefits:

- Provides pathogen free sludges

- Complies with PAS110 and ABP regulations

- Extremely Energy efficient

- Very small footprint

- Designed specifically for difficult digestate applications

- Full traceability

- Easy clean Heat exchangers

Technical Data:

- Treatment Capacity: 25 m³/hr

- Footprint: 13m x 10m - main slab / 4m x 3m - pump slab

- Max Height: 9.7m

- Dry Weight: 18,000 Kg approx.

- Operational Weight: 87,000 Kg approx.

- Hot Water Supply: 22 m³/hr @ 85°C (recirculated)

- Power Demand: 45 kW

Downloads

Brochure