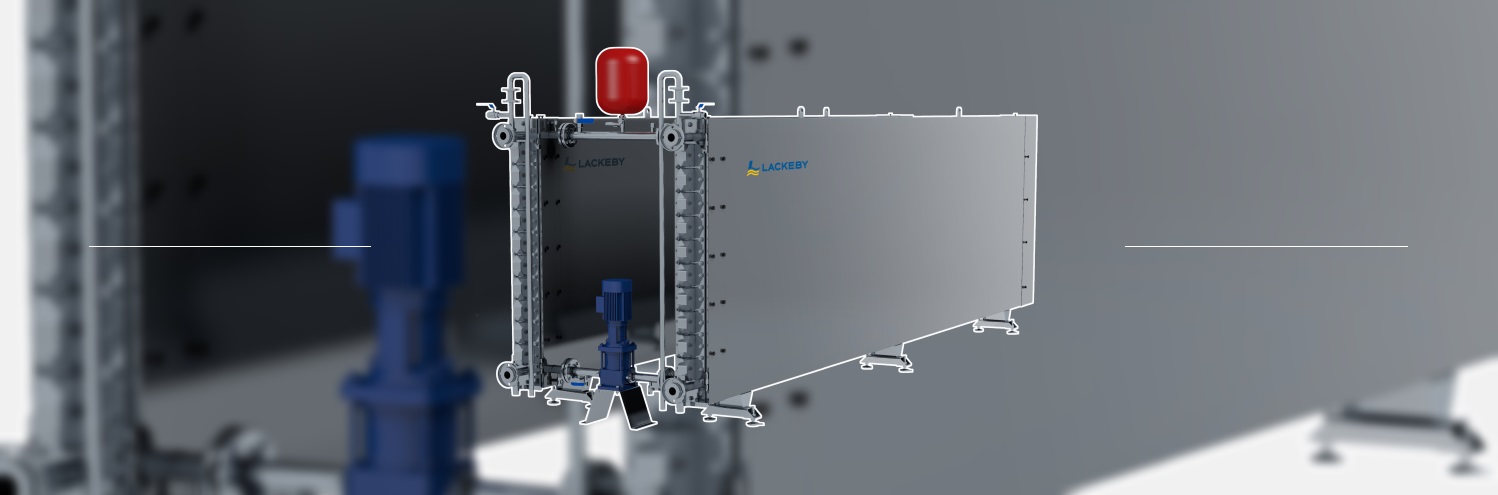

Lackeby Heat Exchanger - Sludge / Sludge

The Lackeby Heat exchanger sludge / sludge unit consists of two heat exchangers sludge / water connected by a closed water circuit. This creates a compact unit that is simple to install and minimises installation volume. The closed water circuit between the heat exchangers eliminates the risk of digested or pasteurised sludge being contaminated by raw sludge. Circular sludge channels deliver a large throughput area, which means low pressure loss and a minimised risk of clogging.

Inspection, disassembly and maintenance are made easier because the patented turning chambers are mounted on a common flange. The turning chambers also provide higher temperature transfer by equalising the sludge temperature profile. Based on a modular principle and patented turning chambers, the compact design delivers low running costs.

Benefits

- Enhances efficiency of digestion and pasteurisation

- Minimises installation volume

- Minimises risk of clogging

- Makes maintenance easier and eliminates problems with multiple flanges and loose connections

- Equalises the sludge's temperature profile

- Reduces pressure losses

- Eliminates risk of sludge contamination

Technical Features

- Unique design specifically for sludge

- Compact unit that is easy to install

- High heat transfer

- Closed water circuit between two separate heat exchangers

- Patented turning chamber

- Simple inspection and maintenance

- Large throughput area