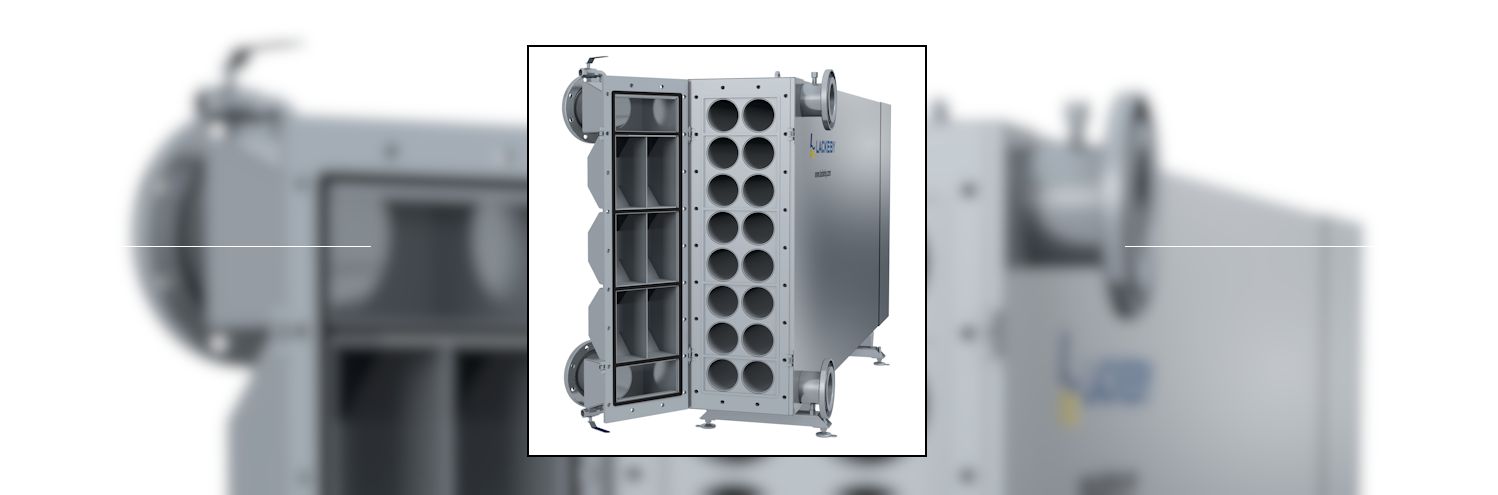

Lackeby Heat Exchanger - Sludge / Water

Lackeby Heat exchanger sludge / water are produced based on a modular principle, with circular sludge channels, which means the design can be adapted to each plants unique conditions. The channels provide a large throughput area that keeps pressure loss low and minimises the risk of clogging. Each level of sludge channels are surrounded by a rectangular water circuit, in which water for heating/cooling flows in the opposite direction to the sludge. The unique patented open turning chamber contributes to a compact design and is simple to install.

Inspection, disassembly and maintenance are made easy because the turning chambers are mounted on a common flange. The turning chambers provide even higher heat transfer by equalising the sludge temperature profile.

Benefits

- Enhances efficiency of digestion and pasteurisation

- Eliminates problems with multiple flanges and loose connections

- Equalises temperature profile of sludge

- Reduces pressure losses

- Minimises risk of clogging

Technical Features

- Unique design specifically for sludge

- Patented turning chamber

- Compact unit that is easy to install

- Simple inspection and maintenance

- High heat transfer

- Large throughput area

Downloads

Brochure